Hammered Anodized Titanium Ring

Each ring is individually hand-formed from solid titanium and finished with a sculptural hammer texture that catches the light from every angle. The color is created through anodizing—a process that uses electricity to transform the surface of the metal—resulting in luminous hues that are part of the titanium itself, not paint or plating. Lightweight yet incredibly strong, titanium offers a modern alternative to traditional metals. The hammered surface adds depth and movement, allowing the color to shift subtly with wear and light.

Over time, the ring develops a quiet patina, with soft highlights appearing on raised areas—an organic evolution that reflects how the piece is worn and lived in. Designed to be comfortable for everyday wear, this ring is hypoallergenic, tarnish-free, and made to last. Each piece is finished by hand in my California studio, making every ring unique.

Lisa is drawn to titanium for its strength, lightness, and ability to hold color in a way that feels both modern and timeless. The hammered texture ensures no two rings are ever the same—each one reflects the rhythm of my hands and the moment it was made.

Want to Learn More About Titanium?

I wrote a full blog post that answers the most common questions about titanium jewelry—how it’s made, how strong it is, whether it tarnishes, and why it’s often a great choice for sensitive skin.

Read the article: 10 Facts About Titanium Metal Jewelry

This video shows rings from the MONOLISA Rainbow Titanium Collection and the anodizing process that creates each ring’s one-of-a-kind rainbow color. The vibrant hues are achieved by altering the surface of the titanium using an electrical process—no dyes, paints, or coatings are used.

Ring Details

- Solid titanium

- One of a kind

- Hammer-textured finish

- Anodized color (no dyes or coatings)

- Lightweight, strong, and hypoallergenic

- Comfort-fit interior

- Handmade one at a time

- Bay Area made

Care

Remove before heavy manual work or contact with abrasive surfaces. Clean gently with mild soap and water. Avoid polishing compounds, which can alter the anodized surface.

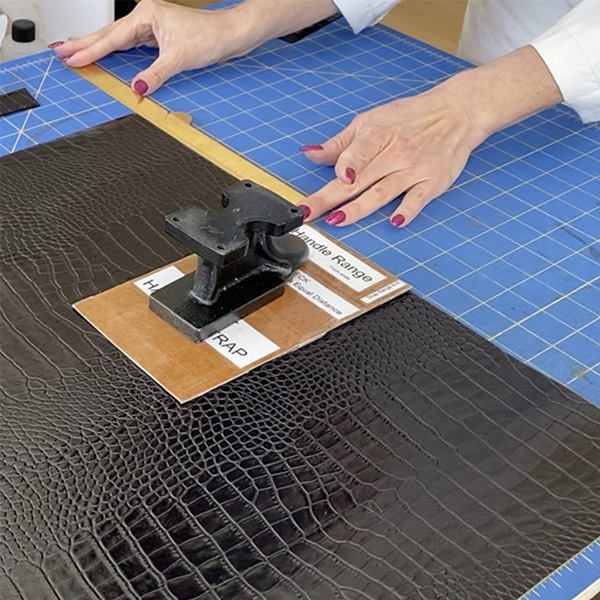

The Handmade Process

Each ring is handcrafted one at a time by me, Lisa Ramos, in my Clayton, California studio. Every design is approached slowly and intentionally, allowing the material and process to guide the final form—never mass produced, never rushed.

The process begins with sourcing quality titanium, followed by developing a one-of-a-kind ring design. Each piece is shaped and textured by hand, with select designs carefully welded as part of the construction, then hardened through a burnishing process. The ring is finished with anodizing, a controlled electrical process that transforms the surface of the metal to create lasting color without dyes or coatings.

MONOLISA designs are available exclusively through this website and at select juried fine art shows.

How it Wears Over Time

Anodized titanium does not fade, but like all fine materials, it responds to daily life. The color may soften on the highest points of the texture over time, creating subtle contrast and dimension. This natural wear is part of the character of the piece. Rings can be re-anodized in the future if a color refresh or change is desired.

My Design Process

“My mission is to design beautifully handmade limited-edition pieces that add a touch of elegance to any personal style. Each design is an extension of who I am, shaped by curiosity, experimentation, and craftsmanship.”

Learn more in my Artist Life Blog .